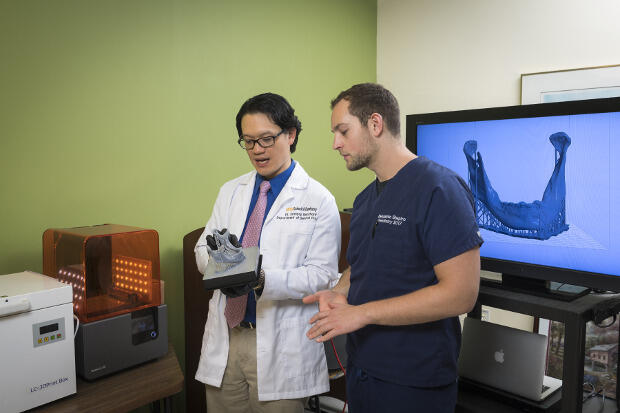

<br>Photo by Allen Jones, University Marketing

Nov. 9, 2017

Digital dentistry is bringing technology to the classroom and the clinic

Share this story

On a Wednesday morning this past summer, Sompop Bencharit, D.D.S., Ph.D., was showing visitors around his lab. He held in his hand the model of a 16-year-old girl’s bottom jawbone, which was bulging and asymmetrical on the left side.

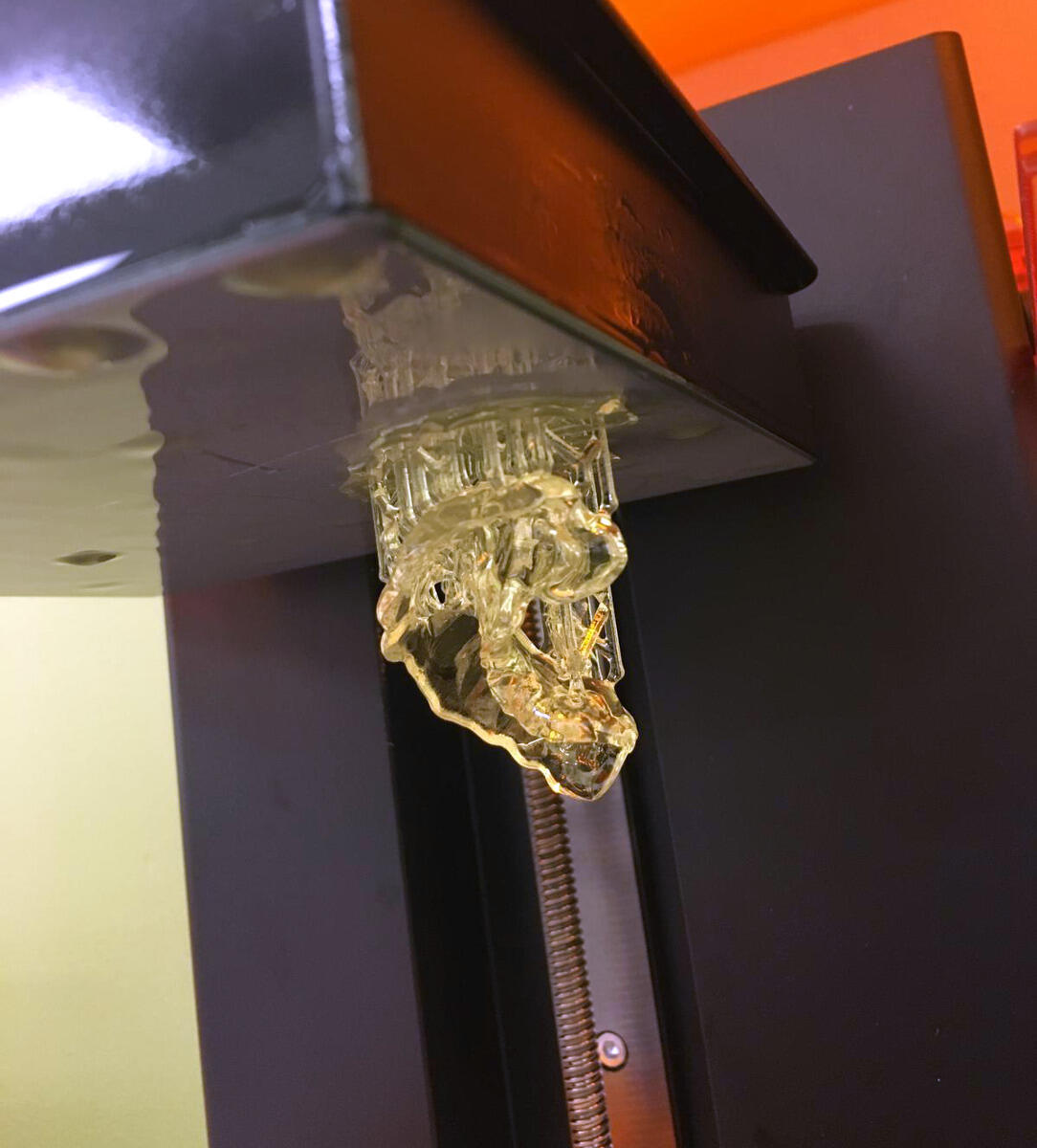

One of Bencharit’s students at Virginia Commonwealth University School of Dentistry had just made the model using a dental imaging scanner and the lab’s 3-D printer. It showed the symptoms of fibrous dysplasia, a bone disorder in which tissue develops in place of a normal bone and causes the bone to deform or fracture.

In just a few hours Bencharit would pass the model to the girl’s oral surgeon, who would then practice shaving the bone to a normal shape on a model identical to what she would see in the operating room.

The digital process and tools used to make the model, and the fact that a student created it, are reasons David Sarrett, D.M.D., dean of the dental school, recruited Bencharit last year to come to VCU.

Digital dentistry is here and it is changing almost everything we are doing to restore and replace teeth.

“Digital dentistry is here and it is changing almost everything we are doing to restore and replace teeth,” Sarrett said. “We needed a person to drive change and adoption of this technology, and Dr. Bencharit was a perfect fit. He is a leader in digital dentistry application and a great teacher and mentor for students and the faculty.”

Sarrett hired Bencharit in 2016 as the school’s first director of digital dentistry, a position that allows Bencharit to explore and teach emerging technology in the classroom and apply the best new tools and procedures in the clinic.

As Bencharit builds the school’s digital dentistry curriculum and clinical support, administrators are planning to give his lab a permanent home. They are exploring options in an upcoming MCV Campus expansion project, which could include a dedicated space alongside pre-doctoral, residency and faculty dental clinics. Establishing a digital dentistry lab next to these clinics will enable Bencharit, his team and his students to work with other dentists to deliver the most advanced care available, which is less invasive, faster and more precise.

Digital dentistry in action

The curriculum Bencharit is shaping and the tools he has introduced are already creating less invasive experiences for patients and more accurate work on the part of dentists and surgeons.

For example, Bencharit implemented intraoral scanning and digital impressions in the clinic and dental curriculum. As opposed to traditional impressions that require a material to be mixed, sit in a patient’s mouth and then harden, digital impressions take roughly five minutes and are made using a handheld scanner. The scanner Bencharit and his students use takes 1,400 to 1,500 pictures and creates an exact digital model that can be examined on screen or 3-D printed in the lab.

“The 3-D impressions are easier for the patient and for the dentist,” Bencharit said. “They also make you a better dentist because they are more accurate and easier to see, allowing you to check your own work. You can go to the screen and magnify them, and if they don’t look right, you can make adjustments and scan again.”

Digital impressions on their own aid dentists in making crowns, bridges, orthodontic treatments and mouth guards. When additional technology is used, dental surgery and implant procedures are drastically improved. Cone beam computed tomography, or CBCT, is technology used to produce 3-D images of soft tissues, nerve pathways and bone in a single scan. It is what Bencharit’s students used to create the model of the jawbone of the girl who suffered from fibrous dysplasia.

When CBCT information is combined with precise intraoral digital impressions, a complete and detailed model of the jaw and teeth emerges that shows the relationship between soft tissue, teeth and bone.

With the model, Bencharit is able to design and 3-D print customized surgical implant guides that fit into a patient’s mouth. The guides cover surrounding teeth and include a tube that directs screw access, angulation of the implant in relation to the bone and vertical position of the implant.

This fall, the School of Dentistry is offering one of the first courses in the country focused on this type of computer-assisted implant planning and guided surgery. Fourth-year students will pair with oral surgeons to complete intraoral and CBCT scans of patients, plan a surgery using the digital information they’ve gathered, 3-D print surgical guides and place an implant.

The new techniques that students are using at VCU School of Dentistry are creating new standards in dental care, one of which is a drastically reduced time commitment for patients and dentists. Placing crowns, for example, previously required conventional impressions to be made and then sent to a lab for one to two weeks. The crown would then be sent back to the dentist’s office, where the patient returns for crown placement. Using the technology in Bencharit’s lab, digital impressions can be made and analyzed in the lab, and then a crown can be fabricated in an on-site mill in one day.

“Dentistry constantly changes, but there are a few things in the past that were milestones,” Bencharit said, adding that 30 years ago the milestones were adhesive dentistry and modern implants. “The next breakthrough, what we are going through now, is digital dentistry. Even though digital has been around for a long time, the technology of the scanner and the computer design of the crown have not caught up until now. I came here because the school had the vision to integrate digital dentistry into the dental student and resident curriculum, and I want to be part of the new wave.”

Subscribe for free to the VCU News email newsletter at http://newsletter.news.vcu.edu/ and receive a selection of stories, videos, photos, news clips and event listings in your inbox every Monday and Thursday during the academic year.

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.