Aug. 8, 2016

VCU alumnus creates custom medical devices for service members

Share this story

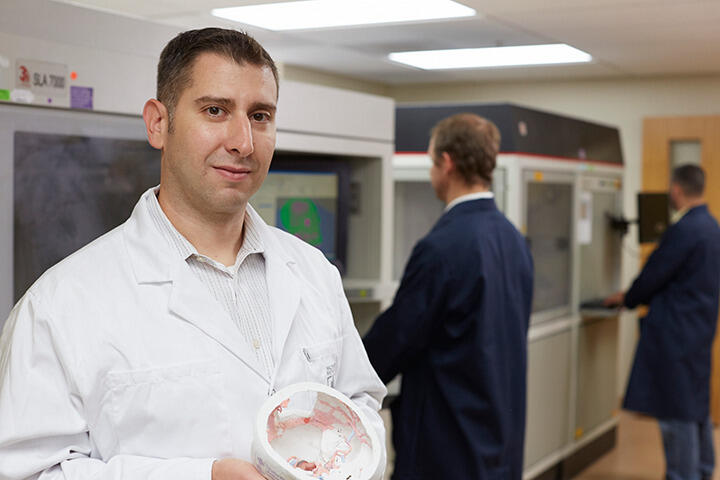

Using sophisticated 3-D printers, Peter Liacouras, Ph.D., is helping shape the next generation of medical devices.

Liacouras earned his master’s degree in biomedical engineering from Virginia Commonwealth University in 2002. Soon after completing his Ph.D. at VCU in 2006, he joined the 3-D Medical Applications Center at Walter Reed Army Medical Center as a senior medical engineer. After Walter Reed and National Navy Medical Center merged in 2011 Liacouras became director of services at 3-D MAC, a leader in additive manufacturing of medical devices.

His work often puts him at the forefront of life-enhancing innovations for service members returning from the front lines with serious injuries. One example is “shorty feet,” a supplementary prosthetic that allows bilateral amputees to mobilize without having to use their full prosthetic legs.

“We created the first pair in response to a request from the chief of the military advanced training center and lead prosthetist, who wanted a one-off for a patient to take on his honeymoon,” Liacouras said. “We designed the device in CAD, printed a plastic prototype for a fit test, and then printed the permanent version in titanium alloy. The prosthetics department quickly saw the usefulness of the device. Since July 2012, the 3-D MAC has produced more than 70 pairs of ‘shorty feet.’ They are now used in training, at a pool or beach, to easily play with a young child, or something as simple as getting up in the middle of the night.”

To help amputees return to pre-injury activities, 3-D MAC also makes custom prosthetic attachments for holding fishing rods, wearing ice hockey skates, rock climbing, or playing musical instruments.

Another area of expertise of 3-D MAC is to construct presurgical models from radiological scans. Medical models were the foundation of the lab in 2002. Since then more than 8,000 surgical models have been printed. Liacouras has used these models to produce patient-specific implants including mandibular spacers, custom cranial plates for shrapnel wounds, and dental meshes that promote bone regeneration prior to implant placement.

Recently, Liacouras has helped to expand the offerings of 3-D MAC to include low-cost simulation models to assist in resident and provider training.

“It is estimated that the models can cut 30 to 90 minutes off of a procedure,” Liacouras said. “Some of the surgeons say that when they are performing the operation, it feels like they have been there before.”

Liacouras said the simulation work he undertook for his dissertation research at VCU — under the direction of Jennifer Wayne, Ph.D., in Wayne’s orthopedic research laboratory — was a perfect transition for his work at Walter Reed. His work with Wayne generated computer models that describe how the foot and ankle function when a person walks. In developing those computer models for his dissertation, Liacouras used many of the tools he continues to apply in his work with Walter Reed today.

As for the future of 3-D medical device printing, Liacouras emphasized that evolutions are driven by patient care.

“There are always new areas,” he said. “The next improvements depend on what returning service members need. The next breakthrough changes daily.”

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.