July 12, 2016

Tiny Tech: A startup bringing big changes to protective clothing

Share this story

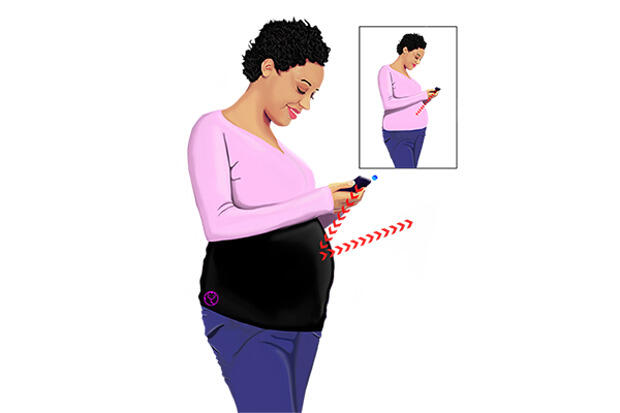

As cell phones and other wireless technologies proliferate, there is growing concern about the health effects of the electromagnetic radiation these devices emit. Tiny Tech, a startup from the Virginia Commonwealth University School of Engineering, is addressing those concerns by weaving effective EM radiation shielding into clothing.

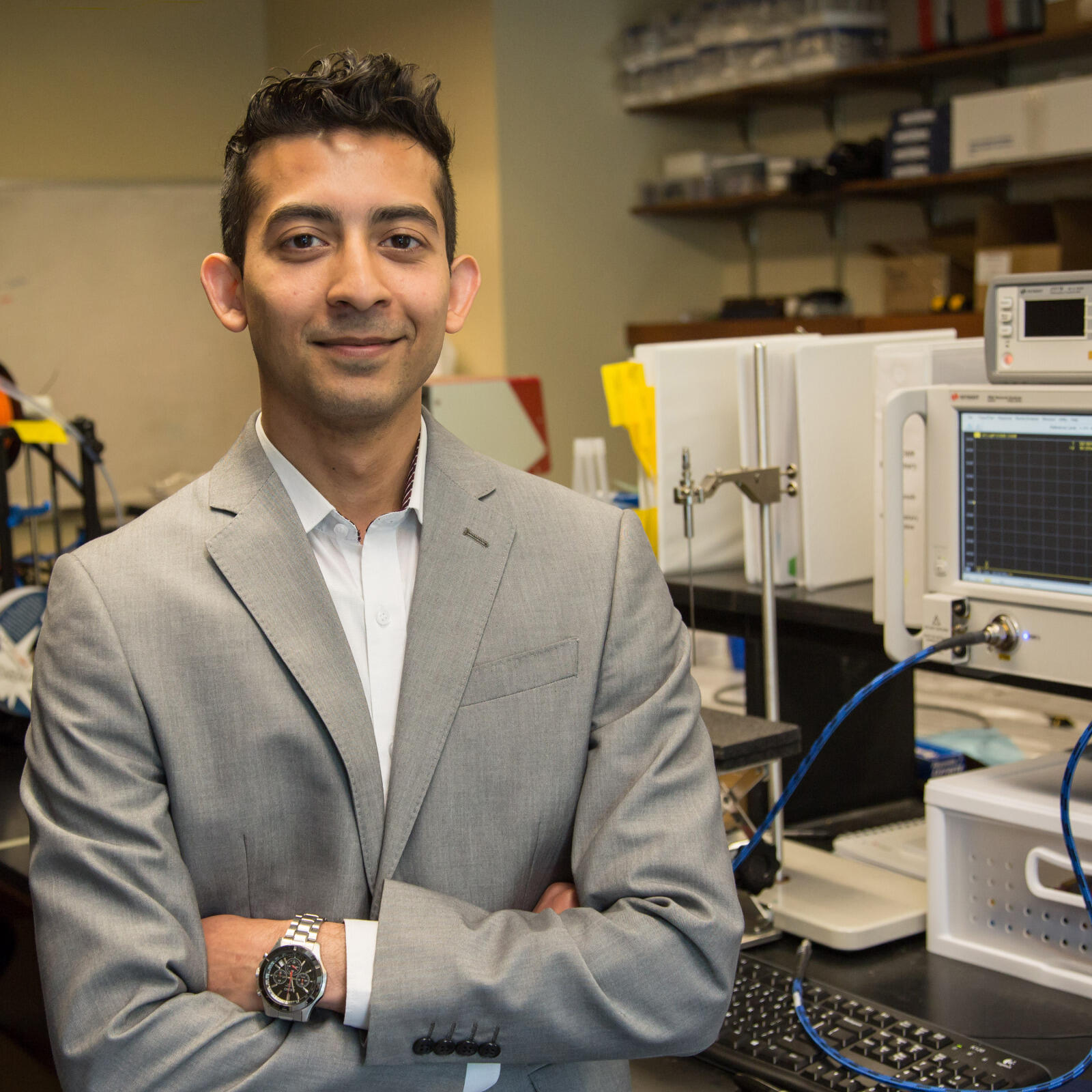

The Tiny Tech team brings together talent from the School of Engineering and the VCU Brandcenter, which is part of the School of Business. Umar Hasni, a Ph.D. candidate in electrical engineering, and Margaret Karles, a student in the Brandcenter’s Experience Design Program, have joined Erdem Topsakal, Ph.D., professor and chair of the Department of Electrical and Computer Engineering, to develop the product and form the company. They are united in their enthusiasm for technology, and in their commitment to make it safer.

“In the age of connectivity, everything is at the touch of our fingertips,” Hasni said. “In order to make that happen, radio frequencies and microwave frequencies are connecting everybody’s devices. You can’t stop technology from progressing — you want it to do better. So we’re focusing on how we can still progress in technology but keep ourselves safe as well.”

Selectively screening EM radiation

Connections between electronics and health are a longstanding interest for Topsakal, whose electrical engineering research includes health care applications of microwaves. After his father’s death from lung cancer, his interests turned to the possible relationship between radio waves and cancers.

“The European Commission declared EM radiation potentially carcinogenic, and I needed to know more,” he said.

He also examined an important 2012 Yale University study in which pregnant laboratory mice exposed to ordinary cell phone radiation produced offspring that were more hyperactive and had poorer memories compared to a control group — essentially the characteristics of ADHD. Fetuses and infants have thinner skulls, so it made sense to Topsakal that they might be most susceptible to the effects of radio waves.

“That was when the light bulb came on,” he said. “You could develop fabrics for garments that selectively screen out EM radiation.”

But why screen out EM radiation selectively? Topsakal explained that a 100 percent reflective surface is essentially a metal sheet, the kind of thing being manufactured overseas today. Those garments are expensive and notoriously uncomfortable. Worse, their stiff fabrics create openings, usually around the arms and neck, which allow radio waves in and can even keep them from escaping.

Using its patent-pending technology, Tiny Tech is able to produce fabric flexible enough to fit the body’s contours comfortably while also screening out 99.9 percent of EM radiation waves.

The team thinks that one of Tiny Tech’s greatest strengths is the fact that it is streamlined enough to make EM radiation protection affordable.

“The reason we are able to make it so cost effective is because it is so brutally simple,” Hasni said. “I could tell you how to make it and you could go home and make it. It would be very crude, but … ”

“Beautifully simple, not brutally simple,” interjected Karles, who leads the branding side of the startup and designed the first proof-of-concept prototype.

They are rolling the product out to expectant mothers first. Consumer data indicate expectant mothers, who number approximately 4 million annually in the U.S., are particularly concerned about EM radiation, Karles said. Some pregnant women are removing wireless technologies from their homes and going back to hard wiring.

Growing the brand

Tiny Tech has attracted multiple investors. It received $5,000 from the VCU Pre-Accelerator Program, which also designated Tiny Tech as “Most Scale-able Company.” It also won $4,000 from the VCU Venture Creation Competition. Most recently, it was awarded $15,000 from the VCU Quest for Innovation Commercialization Fund. The team is applying for the Richmond-based Lighthouse Labs Accelerator Fund, along with a few other accelerator programs. In the meantime, the Tiny Tech team members will use their $24,000 in seed capital to produce and test prototypes this summer.

“We will wash the garments a hundred times to make sure they are still effective,” Topsakal said. “We will also have people trying them on to make sure the clothes are comfortable.”

The team believes that VCU has also enriched Tiny Tech’s development in ways that go beyond financial support.

“There are incredible resources that were always available to us,” Hasni said. “We’re using a network analyzer. And when you get to work with people from different backgrounds, you learn so much. That is one of the key things that VCU facilitated.”

After this summer’s intensive prototyping phase, the team would like to see a soft launch, with online sales starting next summer. In 2018, they will assess and evaluate the company. They plan to license the Tiny Tech process to clothing manufacturers and would like to see the Tiny Tech brand become as ubiquitous, and as trusted, as cotton.

“People will see our logo and know, ‘Oh, Tiny Tech is protecting these clothes,’” Karles said. “We think it will be one of the things that make a piece of clothing something you want to wear.”

Subscribe for free to the weekly VCU News email newsletter at http://newsletter.news.vcu.edu/ and receive a selection of stories, videos, photos, news clips and event listings in your inbox every Thursday.

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.