March 2, 2022

Advanced materials for missions to the moon — and beyond

Share this story

NASA is hard at work on projects to send humans back to the moon — and eventually onward to Mars.

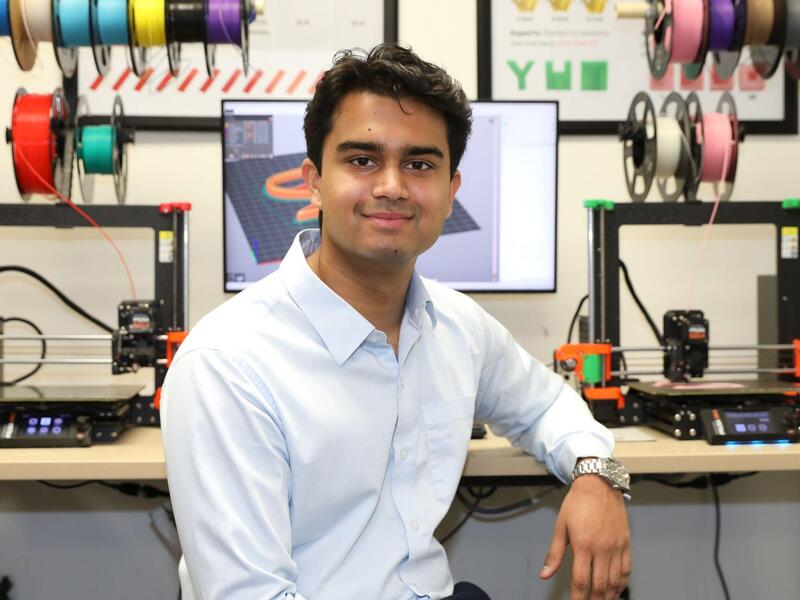

Ibrahim Guven, Ph.D., an associate professor in VCU’s Department of Mechanical and Nuclear Engineering in the College of Engineering, is part of a collaboration that will help NASA meet its goal of sending a manned mission to Mars in coming years.

Guven is part of a 10-university team led by Michigan Technological University that has been working with NASA to develop an advanced structural material for the mission.

An internationally recognized expert in computational models for fracture and materials failure analysis, Guven is applying his skills in nondestructive testing and modeling complex materials to help meet the challenges of this new technology.

Spacecraft that will transport humans to deep space must be able to withstand extreme changes in temperature and air density. These vehicles also will have to stand up to potentially devastating impacts when hitting even tiny particles.

Since 2017, Guven and his collaborators have been developing a structural material that is strong enough to be safe — but lightweight enough to be practical — when sending humans into deep space. This substance will ultimately be used as the main load-bearing fuselage of a spacecraft. It would also be suited to manufacturing cargo containers to transport samples and other materials back to Earth.

Lightness is paramount. The cost of transporting 1 pound of weight to the moon and back is currently about $100,000, Guven said, and the cost of sending a pound to Mars and back is roughly $1 million. At those prices, “you don’t want to just jump off the spacecraft, get a scoop of Mars material and come home,” he added with a laugh.

Guven and his colleagues are designing an ultrastrong, ultralight material based on carbon nanotube composites. This new material will be far stronger and lighter than currently available substances.

Nanotubes are “strong, predictable structures,” Guven said, likening carbon nanotubes to “rolled-up slices of graphene.” Carbon nanotubes can be stretched and twisted into a “yarn” for use in a fiber-based composite, he explained. These long fibers can be woven to form sheets or tapes. They can also be “braided” into lattice-like structures.

Whether the finished material takes the form of tapes, sheets or woven lattices, much of the work to develop it is computational. Simulations permit the researchers to model the extreme conditions of space travel, including reentry into Earth’s atmosphere, and to push and stretch the specialty material to its limit.

Ultimately, the research team will deliver to NASA a computationally driven design paradigm for rapid development of this carbon nanotube composite, as well as other advanced materials.

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.