May 11, 2023

Students present innovative research and prototypes at VCU College of Engineering design expo

Share this story

A vertical, soil-less garden. A clothes dryer that uses vacuum technology instead of heat. A system that precisely tracks wheel-based equipment.

These were some of the innovative prototypes unveiled by more than 90 student teams at this year’s annual Engineering Capstone Design Expo.

A signature event of the Virginia Commonwealth University College of Engineering, the annual Capstone Design Expo represents the culmination of the graduating class’s education and offers design teams the opportunity to display and demonstrate their working prototypes to the Greater Richmond community.

The projects are the product of a yearlong Capstone Design course, led Laura Osborne, College of Engineering events and engagement administrator, and a team of faculty representatives from each department, which immerses senior engineering students in the hands-on processes of solving practical problems.

Through their projects, student teams practice customer discovery, the engineering design process and rapid prototyping. Working with sponsors, students tackle this practical learning experience by solving real-world problems under real-world constraints, learning fundamentals of teamwork and applying learned theory.

Here are some of this year’s projects.

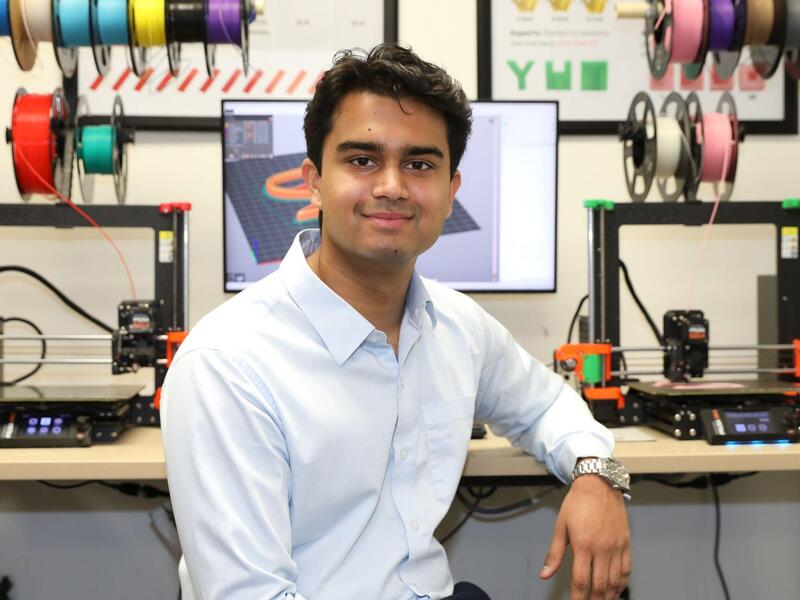

3D Printed Lower Limb Prosthetics

Department: Biomedical Engineering

Team: Rayyan Amer, Tylar Brinkley, Miriya Philip

Adviser: Henry J. Donahue, Ph.D.

Sponsor: Saad Sheriff

For amputees, a prosthetic allows them to continue with life as normal, but those attachments pose certain challenges. An improper fit at the socket — where the residual limb connects to the prosthesis — often causes tissue damage, which can trigger inflammation or shrinking, making the simplest of tasks difficult.

This capstone team designed a smart socket that uses sensors to detect changes in pressure and alerts the user to adjust the socket. It can also come with a liner, similar to wearing a sock with a shoe, to make the socket more comfortable against the skin.

When patients lose sensitivity in their residual limb, they don’t realize the damage it has done until it’s severe. The smart socket allows patients to avoid more trips to the doctor and high medical bills.

Nontraditional Gardening for Urban Nonprofits

Department: Chemical and Life Science Engineering

Team: Ahmed Tewfig, Mohammed Safar, Randolph White, RJ Peters

Adviser: Thomas Roper, Ph.D.

Sponsor: VCU Inclusive Excellence

Food insecurity – a lack of access to sufficient food to lead a healthy life – forces many to go without fresh, quality produce. Localized food production is one approach, but it’s unsustainable in urban areas due to lack of land and soil.

The solution is a vertical garden, where crops grow on shelves stacked on top of each other. The team chose a hydroponic garden, a method of growing plants without soil, where the roots are submerged in flowing water. The low-maintenance system only requires keeping the water reservoir at the bottom of the garden full and monitoring its nutrients. The students used Hahms Gelbe tomatoes for their prototype due to its nutrient density and short growing cycle.

The goal is a cost-effective system for urban nonprofits to provide food to individuals experiencing food insecurity.

Real Time Indoor Wheel-Based Asset Localization System (Overall Awards - 2nd place winner)

Department: Computer Science

Team: Sam Castle, Eva Curry, John Sfara, Nicole Tome

Adviser: Tamer Nadeem, Ph.D.

Time is money. And for those in industries such as health care and manufacturing without a system to locate and track assets, time is wasted that could be used on other responsibilities.

This team created a system that locates any wheel-based asset — such as wheelchairs or forklifts — with fine-level accuracy. Two gyroscope sensors located on each wheel generate data that the system tracks in real time. With the help of an algorithm, a user-interface monitor shows the exact location of the asset, including the path and distance it traveled and the direction it’s currently facing.

The system serves as a foundation for other uses, from monitoring vehicles for training and insurance purposes to mapping areas of high-risk zones, such as a nuclear fallout site, where human intervention isn’t feasible.

Macro-diversity in Future Wireless Cellular Networks

Department: Electrical Engineering

Team: Coby Cockrell, Radiah Zaman, David Bordenkircher

Adviser: Ruixin Niu, Ph.D.

Sponsor: Army ASPIRE

On any given day in downtown Richmond – with vehicles zipping by, office and school buildings using various networks, and people using cell phones all at once – transmitted signals scatter. The clutter and motion distorts these signals, causing fading or corruption.

With cities in mind, these students designed a spatial communication system that enhances coverage and reduces signal errors with the use of macro-diversity. In simpler terms, receivers are spaced apart with a transmitter in the middle that conducts a signal. Receiving multiple outputs of a single input enables diversity combining, which reduces the signal distortion of cell phones and other connected devices such as smart watches, wireless printers and security systems.

The goal is to improve the communication link by reducing the bit error rate in rich scattering environments such as office buildings, schools and warehouses to lower energy consumption and increase coverage.

Vacuum-Driven Clothes Dryer (Mechanical & Nuclear Engineering - 3rd place winner)

Department: Mechanical and Nuclear Engineering

Team: Roman Cutler, Amadi Shekanino, Kirollos Abdou, Noorpreet Kaur

Adviser: Carlos Castano Londono, Ph.D.

Sponsor: Anand Lot-he

Drying clothes takes a significant amount of time and energy in large-scale facilities such as hospitals and laundromats. The high heat from traditional dryers also decreases the quality of fabrics, forcing users to replace them often.

Looking to make existing vacuum ovens — which dry heat-sensitive materials without heat — more efficient, the students attached sensors to the device to measure variables including the temperature of the chamber and fabric, humidity, pressure and the amount of water evaporation. The team’s first attempt at modifications dried 152 folded medical gowns — a 70-pound load — in two hours and used 1500 kWh of power.

After experimenting with various configurations, the students developed a design that maximized surface area exposure, resembling a closet, dramatically reducing both drying time and energy use. The new design dries a 70-pound load in just 20 minutes, consuming a mere 250 kWh of power.

Data Visualization and Storytelling in VR

Departments: Computer Science, Computer Engineering, Electrical Engineering, Kinetic Imaging

Team: Cole Bohanon, Jason Roark, Joseph Theakston, Tyler Samay, Ty Glisan, Esther Kim, Uday Illa

Advisers: Robert Dahlberg, Ph.D., Nathaniel Kinsey, Ph.D., Semi Ryu

For electrical engineering students, electromagnetic concepts are difficult to understand just from sitting in a lecture, reading a textbook and taking notes. This makes multisensory learning a crucial step for students to put these models to use.

This multidisciplinary team’s virtual reality system helps engineering students better visualize concepts such as Coulomb’s, Gauss’s and Ampere’s law (dealing with the interactions between two charges, the flux over a closed surface and the circulation of a magnetic field along a closed path, respectively). VR is unlike traditional learning in that it involves touch, providing students with hands-on training. This improves their understanding both inside and outside the classroom, as they can be used anywhere.

Students can make dynamic changes in the technology, seeing the effects in real time. In the future, this can be used in workplaces and classrooms in areas such as mathematics, natural sciences and the medical field.

Best Industrial Project Award

ECE 23-401: Analog Wideband Beamformer

Team: Miles Dawkins, Dustin Hulse, Mac Salter, Dan Youngk

People's Choice Award

BME 23-104: Postural Orthostatic Tachycardia Syndrome (POTS) Monitoring Device

Team: Zainab Alibrahim, Anica Huang, Julia Som, Nikhat Nusrat

Overall Awards

1st place

CS 23-321: Web App for Assessing Prewriting Skill in Children

Team: Charlie Cutler, Edward Ladia, Noah Shields, Christopher Smith

MULT 23-614: Development of 3D Printable Brain Phantoms for Ultrasound and Concussion Testing

Team: Parisa Zalmai, Benjamin Reams, Anthony Rubio-Tonche, Lila Schandler

2nd place

CS 23-322: Real Time Indoor Wheel-Based Asset Localization System

Team: Sam Castle, Eva Curry, John Sfara, Nicole Tome

3rd place

MNE 23-513: Design and Analysis of a Novel Molten Salt Fusion Blanket Breeder System

Team: Ryan McGuire, Sierra Tutwiler, Trevor Franklin, Amelie Lutz

Departmental 1st Place Awards

Biomedical Engineering

Project: BME 23-111: Integration and Analysis of Neuromonitoring in the Operating Room

Team: Samiya Majid, Yashnoor Sandhu, Saagar Sheth, Samisha Suresh

Chemical & Life Science Engineering

Project CLSE 23-205: Removal of Polyvinyl Acetate Adhesive from Works of Art

Team: Ana Rodriguez Vicuna, Kimberly Penzer, Sid Nimmalagadda, Yousif Alhouli

Computer Science

CS 23-330: Traversing Mars Virtually Through Robotic Movement

Team: Malcolm Breckenridge, Haley Currence, Ian Jaffe, Cyaira Hughes, Miles Popiela

Electrical & Computer Engineering

Project: ECE 23-401: Analog Wideband Beamformer

Team: Miles Dawkins, Dustin Hulse, Mac Salter, Dan Youngk

Mechanical & Nuclear Engineering

Project: MNE 23-509: Design and Development of an Automated Rotary Welding Table with Multiple Adjustments

Team: Logan Deters, Yousef Elsiragy, Youssef Aziz, John Whitman

Multidisciplinary

Project: MULT 23-602: Automation Machinery Fundamentals Kit

Team: Ebenezer Mensah, Matthew Basic, Rodrigo De Leon, Aiden Carr, Ryan Rolle

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.