June 8, 2020

‘We wanted to do something to help’: VCU Engineering lab produces hand sanitizer

Share this story

Hand sanitizer. Toilet paper. Disinfectant wipes.

When the COVID-19 pandemic emptied store shelves of such in-demand products, Thomas D. Roper, Ph.D., figured his Virginia Commonwealth University College of Engineering lab could help with one of them: hand sanitizer.

“We wanted to do something to help during this COVID-19 outbreak,” said Roper, director of pharmaceutical engineering for the college and a professor of chemical engineering.

Earlier this spring the first batch of VCU’s own Ram-Sanitizer — complete with an icon of the university’s ram mascot — became a reality. The hand sanitizer meets the standards of both the U.S. Food and Drug Administration and international World Health Organization. Washing hands with soap and water is the best way to prevent the spread of infections, but when soap and water are not available, the FDA recommends using an alcohol-based hand sanitizer that contains at least 60% alcohol.

Roper said he was looking into organizations that would be interested in funding Ram-Sanitizer and helping to source large amounts of the ingredients. The team hopes to register with the FDA and make larger batches. The first batch, a small test run, was made available to lab members and others working in the College of Engineering.

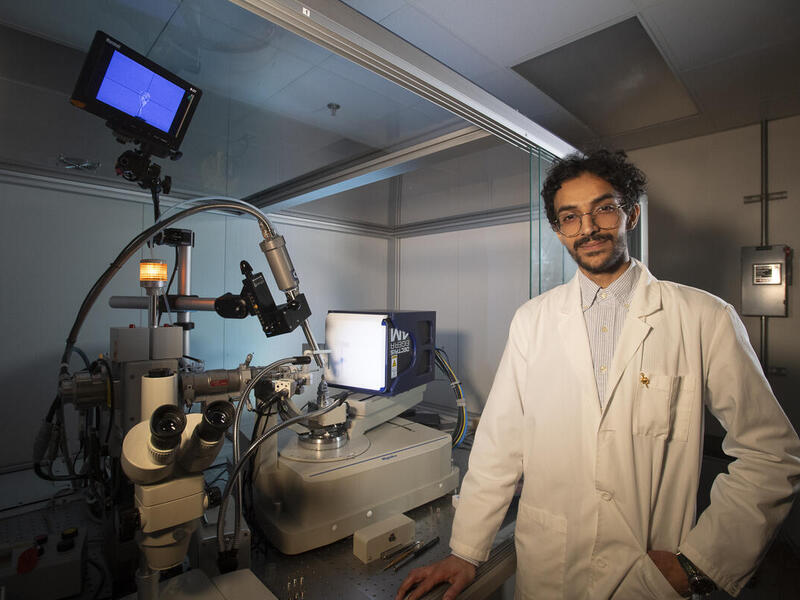

Yuma Miyai, a graduate student in the Department of Chemical and Life Science Engineering who works in Roper’s lab, sourced the ingredients — that are in high demand around the world — used specialized equipment and followed strict protocols in the lab at the VA Bio+Tech Park.

Since one main ingredient, isopropyl alcohol, is flammable, Roper said, “I don’t recommend that people at home do this.” (Neither does the FDA.)

Roper, who is a Virginia Center for Innovative Technology Eminent Researcher, leads a project funded by the U.S. Defense Advanced Research Projects Agency called Pharmacy on Demand. His team has been developing an alternative drug manufacturing process with a miniaturized environmental and industrial footprint. The lab paused its work when the university closed in March, but then it was deemed mission critical by the U.S. Department of Defense in April.

“We were coming back in anyway in order to [work on] the Pharmacy on Demand project and decided to produce a small batch of Ram-Sanitizer,” Roper said.

Miyai said the researchers have created a new system to resume work while following VCU guidelines for social distancing. “Everybody’s very proud of the project that we’re working on.”

Roper said, “The idea of Pharmacy on Demand is that you can produce medicine remotely in multiple locations with a portable device,” such as on the battlefield — or during an outbreak of disease.

“It might be particularly useful in a time like this,” Roper said.

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.