Sept. 14, 2023

Climate tech startup licenses VCU-created insulation for homes, commercial buildings

Share this story

In the fight against climate change, properly insulating homes and buildings can significantly raise energy efficiency and indoor air quality while lowering carbon dioxide emissions. A startup company, spun out of research at Virginia Commonwealth University, is commercializing what it calls a breakthrough in insulation.

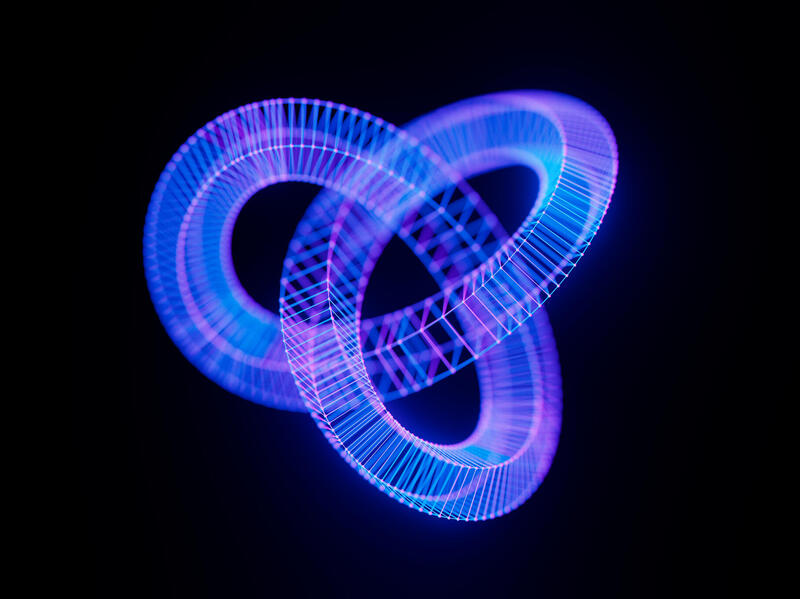

ThermaGEL Innovations has developed insulation material using aerogels, which are porous solids mostly made of air. The company says its aerogel insulation improves heat resistance, known as R-value, by 136% over conventional materials such as fiberglass. Its aerogels are also thinner, lightweight, flame-proof, moisture-proof and reduce noise.

“Aerogels were invented nearly a century ago; however, the process to make them is complex and expensive — until VCU made a breakthrough discovery,” said Marc McConnaughey, president and chief executive of ThermaGEL. “What VCU has achieved with aerogel production could have a significant, positive impact on the environment and support a more sustainable future.”

The science behind the company comes from the laboratory of physics professor Massimo Bertino, Ph.D., at VCU’s College of Humanities and Sciences. Everett Carpenter, Ph.D., a professor in the Department of Chemistry, is also advising the company.

Today, aerogels are a critical super-insulating material for applications ranging from liquid gas tankers and pipelines to space exploration and electric-vehicle batteries. But in general, aerogels are time-consuming and expensive to manufacture under traditional production methods, Bertino said. ThermaGEL hopes to make aerogels a more affordable insulation for homes and buildings through a new production process that would create custom-sized aerogels at a lower cost and greater scale.

An onerous step in current aerogel production is a process known as supercritical drying, which pumps carbon dioxide into a high-pressure reactor, called an autoclave, to form air membranes within the wet gel. The key to making aerogels at a lower cost is to eliminate the supercritical drying process in a way that doesn’t compromise the integrity of the insulation.

“After years of development, we believe we’ve achieved that goal,” said Bertino, who has developed creation and production processes that improve on existing methods. Instead of expensive and potentially dangerous supercritical drying, the aerogels are produced through ambient pressure (nearly room temperature), which is more cost-effective and safer.

Bertino’s intellectual property is protected and licensed through VCU TechTransfer and Ventures.

“This aerogel technology from Dr. Bertino has strong interest nationally, with broad versatility across a number of applications that require super-insulators,” said Brent Fagg, senior licensing manager at VCU TechTransfer and Ventures. “And aerogels are technology that meet the growing needs of a ‘green economy’ while improving safety and energy efficiency.”

Critical to driving ThermaGEL’s revenue, McConnaughey said, is providing its products to building material suppliers, contractors and architects. The company is in the process of raising initial funding to design an aerogel manufacturing facility in the Richmond area.

Carpenter, the company adviser and VCU chemist, said the facility could capture 5% of the U.S. insulation market, which overall is valued at $10 billion annually. Initial capacity will be designed to produce 500 million square feet of insulation per year.

According to ThermaGEL research, the U.S. contains 122 million homes and 6 million commercial buildings mostly built before 1990. Together, Carpenter said, those buildings use one-third of total U.S. energy consumption, with much of it lost due to poor insulation. That leads to higher energy costs and increased carbon dioxide emissions.

“ThermaGEL’s technology could truly help commercial building owners and homeowners save not only on energy costs when it comes to insulation,” he said, “but help the world by removing billions of tons of carbon dioxide from the atmosphere along the way.”

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.