Feb. 13, 2020

VCU researchers to develop next-generation, long-lasting batteries

Share this story

Virginia Commonwealth University researchers in the College of Engineering Department of Chemical and Life Science Engineering will receive a $2.5 million grant from the U.S. Department of Energy to develop next-generation rechargeable batteries.

By redesigning the materials inside lithium-ion batteries, which power everything from smartphones to electric vehicles, the researchers believe they can significantly extend battery life, drive down costs and reduce safety risks for consumers.

“Our goal is to improve the batteries so that they can last longer, be more durable and safer,” said professor Ram B. Gupta, Ph.D., the principal investigator on the project. He is collaborating with Mo Jiang, Ph.D., assistant professor, and Parans Paranthaman, Ph.D., a corporate fellow at the Oak Ridge National Laboratory.

The DOE Office of Energy Efficiency and Renewable Energy’s Advanced Manufacturing Office announced the grant as part of approximately $187 million for 55 projects to support innovative advanced manufacturing research and development. The award was given in the area of innovative manufacturing processes for battery energy storage.

Gupta and his team will test a novel approach for synthesizing material for the battery’s cathode. When a battery is discharging and providing an electric current, lithium ions travel from the negatively charged anode to the positively charged cathode. Conversely, when the battery is being charged, lithium ions move from the cathode to the anode.

With each cycle, Gupta said, there is a slight loss. “By the time you run 300 to 500 cycles, you have lost enough that you would say, ‘I need a new battery.’ We have an idea about how to make this cathode sturdy enough so that the losses are minimized.”

In addition to lowering the cost of batteries, Gupta said this new process would reduce the degradation of material and therefore bring down the risk of explosions and battery fires that happen when the anode and cathode come into contact. “Anytime you have a degradation of the material, then there is more of a chance the two can meet,” Gupta said.

The potential environmental impacts of improving battery material production extend beyond the benefits of increased battery life and efficient use of materials. That’s because batteries are so critical in making sustainable energy alternatives, such as solar and wind power, work.

“I’ve been working on energy for a long time now and batteries are one of the very important parts of the puzzle,” Gupta said.

The Department of Energy grant falls under the agency’s Energy Storage Grand Challenge, which aims to create and sustain global leadership in energy storage.

Previously, Jiang and Gupta received a $529,011 grant from the National Science Foundation to support fundamental work on the concept.

Jiang and Gupta, who are bringing together different specialties in chemical and life science engineering, are seeking a patent for the technology.

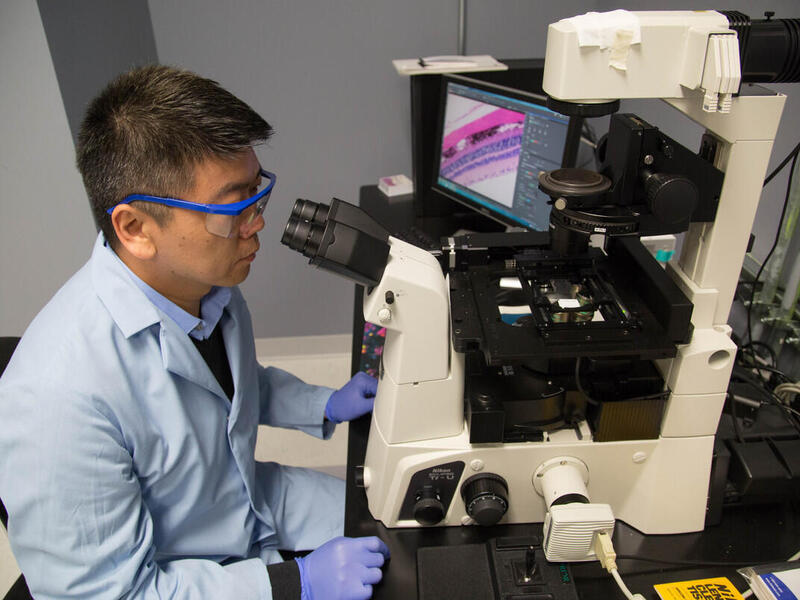

Jiang, whose research focus area is green manufacturing and manufacturing of materials for high-requirement products such as pharmaceuticals, has been developing a reactor manufacturing process that would improve efficiency over the current technologies used to make battery materials.

Gupta, who is also the associate dean for faculty research development in the VCU College of Engineering, researches batteries, sustainable energy and biofuels.

“We came from very different angles. He knew one aspect, I knew another,” Gupta said. “When we put them together, we thought, ‘Oh wow, we can solve this problem.’”

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.